Model No.︰Ni29Co17

Brand Name︰xagy

Country of Origin︰China

Unit Price︰US $ 29.92 / pc

Minimum Order︰10 pc

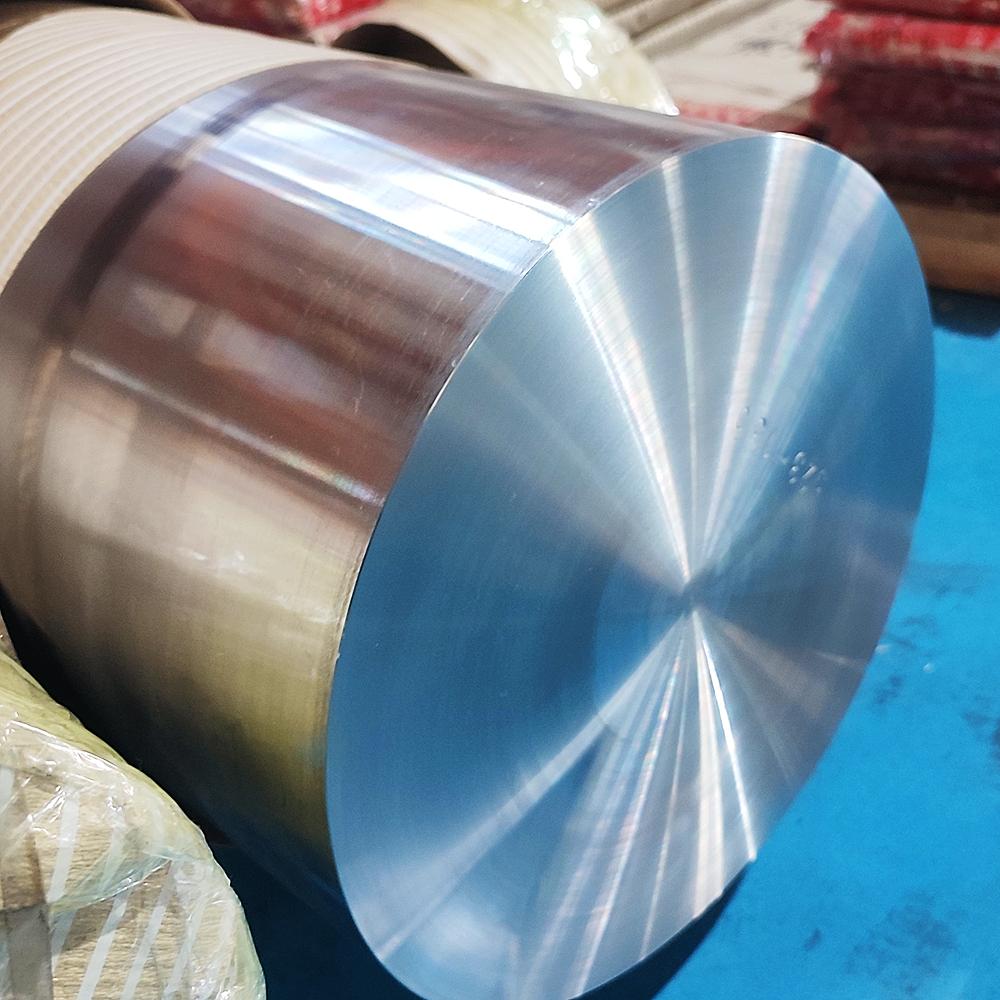

KOVAR Control expasnion alloy ASTM F15

Also known as Rodar, Kovar is a registered trademark that refers to a low expansion alloy that is composed of iron, nickel, cobalt and trace amounts of the elements manganese, silicone and carbon. Kovar was specifically formulated as a sealing alloy for glass and ceramic materials (specifically for compatibility with the thermal expansion characteristics of borosilicate glass).

The alloy is first melted using Vacuum Induction Melting (VIM) techniques. A secondary melt operation, Electro Slag Remelt (ESR), is then employed to further remove impurities and improve overall homogeneity.

| Commerical Trdae Name | KOVAR |

| Material | Nickel-Cobalt-Iron Alloy |

| Specification | ASTM F15-04(2013) UNS K94610 |

| Melting | VIM+ESR |

| Application | hard glass to metal seals |

FORMS MANUFACTURED

| Forms | Dimension Range | Condition |

| Rod | DIA≤500MM | Hot-Rolled or Forged |

| Strip | T0.015MM,Width650Max | Cold-Rolled |

| Sheet | T1.0MM,Width1500Max | Cold-Rolled or Hot-rolled |

| Plate | T6.0MM,Width2500Max | Hot-Rolled |

| Wire | DIA≥0.1MM | Cold-drawn |

Chemical Composition,%

| Ni | Co | Si | Mn | C | Al | Mg | Zr | Ti | Cu | Cr | Mo | Fe |

| 28.5-29.5 | 16.8-17.8 | ≤0.2 | ≤0.5 | ≤0.04 | ≤0.1 | ≤0.1 | ≤0.1 | ≤0.1 | ≤0.2 | ≤0.2 | ≤0.2 | Bal |

Physical Properties

| Density, lb/cu in | 0.302 |

| Specific Gravity | 8.36 |

| Curie Temp,°C | 435 |

| Melting Point,°C | 1449 |

| Electrical Resistivity,mm2/m | 49 |

| Thermal Conductivity,BTU-in/sq. ft-hr- | 120 |

| Specific Heat ,ppm/°C (25°C to 450°F) | 5.3 |

Coefficients of Thermal Expansion

| Temperature Range, °C | Average Linear Coefficient of Thermal Expansion, µm/m·°C |

| 300 to 400 | 4.6-5.2 |

| 300 to 450 | 5.1-5.5 |

Typical Coefficient of Thermal Expansion

| Temperature Range, °C | Average Linear Coefficient of Thermal Expansion, µm/m·°C |

| 300 to 400 | 5.0 |

| 300 to 450 | 5.3 |

Typical Mechanical Properties

|

Tensile Strength Rm MPa |

Yield Strength Rp0.2 MPa |

Elongation A/% |

Reduction Section Z/% |

Hardness Hv |

| 548 | 385 | 42.5 | 78 | 166 |

Important Notice

1. Disclaimer

Every effort is made to ensure that technical specifications are accurate. However, technical specifications included herein should be used as a guideline only.

2. Sample Policy

Kovar are available in many shapes and dimensions,supplying semi-finished products in forms of Strip,plate & Rods.The samples are big enough (typically about 200mm in length for strip or plate) to get an understanding of the material characteristics, meanwhile custom-made sample order available ! small quantity accepted.

3. Payment Terms

30% T/T in advance ,balance before shippment.

4. Who you talking to

Mr. Paul (Designation :Foreign Trade Manager)

WeChat & Phone No: +86 (0)13669288752 (24 Hours)

Skype: alloynickel

Tel: +86 29 3366 9103 ( 08:30-17:30,Beijing Time. Mr.Paul ,Excellent Engilsh & Mandarin)

Fax: +86 29 3369 8670

Http:// www.alloynickel.com

Payment Terms︰ T/T L/C